Gustaaf (Guus) JacobsResearch |

| Summary | Projects |

| Engineering: | Combustors, Drag Reduction (Automotive/Aeronautical), Renewable Energy (Wind Turbines), High Power Microwaves. | Physics: | Multi-Phase Flows, Multi-Scale Physics, Flow Control, Unsteady Separation, Compressible Turbulence, Combustion, Electromagnetics, Plasmas. |

| Applied Mathematics: | High-order Multidomain, Discontinous Galerkin, Spectral h/p Methods, Particle-In-Cell Methods, High Performance and Parallel Computing. |

| Collaborators: | ` Dr. H.S. Udaykumar (University of Iowa), Dr. W.S. Don (Brown University), |

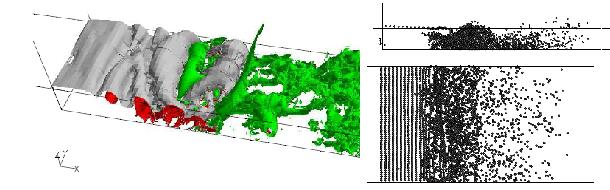

Droplet-laden flow separation is analyzed in the Lagrangian framework, i.e. the

frame moving with fluid particles and droplets, as opposed to the more

common analysis of streamlines and wall friction fields

in the Eulerian frame. In unsteady and three-dimensional

flows, fluid particle separation is suprisingly different from

the Eulerian streamline separation.

In a quasi-periodic unsteady

flow, fluid particles eject away from a fixed wall location

and form an oscillating material line into the flow that is

seemingly unrelated to the unsteady streamline pattern.

This 'fixed separation' has been validated in a rotor-oscillator

experiment as shown in the animation.

The fluid particle separation location in 2D and 3D is, however,

simply identified with time history of wall data

including the wall shear stress and wall pressure data.

In flows with large turbulent fluctuations the fluid particles

separate nearly parallel to the wall and eject away from the wall

into the flow away fromt the fixed separation location.

The separation material line is then better described as moving.

We have recently discovered that finite-sized

droplets may still separate in a fixed manner in these moving

carrier flows.

For more details see the recent news articles:

Droplet-laden flow separation is analyzed in the Lagrangian framework, i.e. the

frame moving with fluid particles and droplets, as opposed to the more

common analysis of streamlines and wall friction fields

in the Eulerian frame. In unsteady and three-dimensional

flows, fluid particle separation is suprisingly different from

the Eulerian streamline separation.

In a quasi-periodic unsteady

flow, fluid particles eject away from a fixed wall location

and form an oscillating material line into the flow that is

seemingly unrelated to the unsteady streamline pattern.

This 'fixed separation' has been validated in a rotor-oscillator

experiment as shown in the animation.

The fluid particle separation location in 2D and 3D is, however,

simply identified with time history of wall data

including the wall shear stress and wall pressure data.

In flows with large turbulent fluctuations the fluid particles

separate nearly parallel to the wall and eject away from the wall

into the flow away fromt the fixed separation location.

The separation material line is then better described as moving.

We have recently discovered that finite-sized

droplets may still separate in a fixed manner in these moving

carrier flows.

For more details see the recent news articles:

|

| Collaborators: |

Dr. G. Haller (MIT),

A. Surana (MIT) |

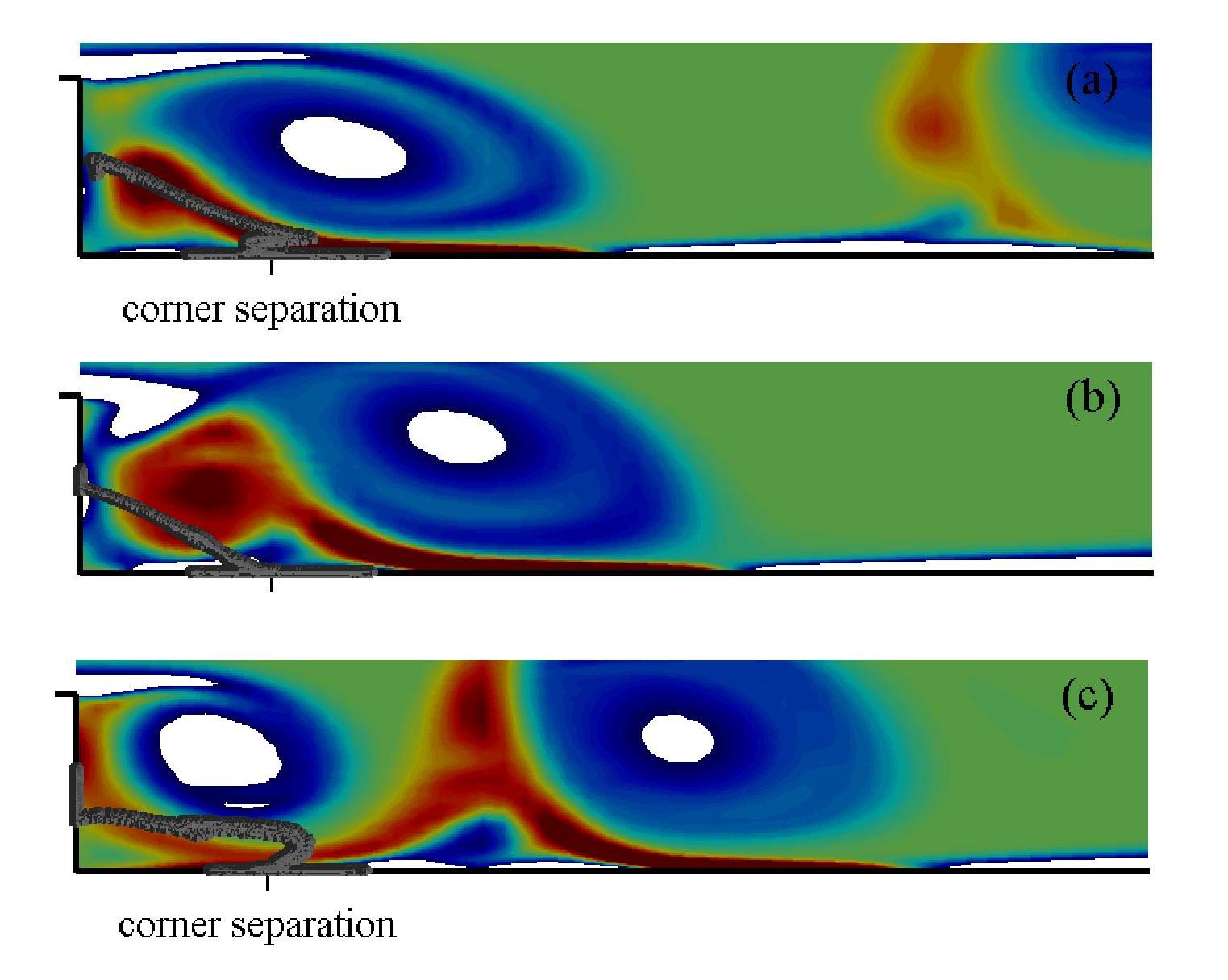

The long term objective of this project is the elucidation

of the combustion physics in liquid-fuel combustors using

simulation tools. To this end,

we compute the droplet-laden, reacting flow in combustor geometries

using Direct Numerical Simulation (DNS)

and Large Eddy Simulations (LES) to

solve the gas dynamics coupled with particle methods to

trace the droplet dynamics. Large-scale computations have

been performed of the droplet-laden flow in a combustor

geometry with a sudden expansion as shown in the figure.

Compressibility effects have been identified to reduce the

recirculation zone behind the step. Control of the cold flow using

a suction slot at the step corner has been shown to be an effective

destabilizer of the shear layer and to

enhance mixing behind the step. Droplet mixing and deposition

is strongly dependent on the injection location in the boundary

layer. Current efforts focus on further parametric studies

to identify the combustion physics, and computations of more

complex combustor geometries.

The long term objective of this project is the elucidation

of the combustion physics in liquid-fuel combustors using

simulation tools. To this end,

we compute the droplet-laden, reacting flow in combustor geometries

using Direct Numerical Simulation (DNS)

and Large Eddy Simulations (LES) to

solve the gas dynamics coupled with particle methods to

trace the droplet dynamics. Large-scale computations have

been performed of the droplet-laden flow in a combustor

geometry with a sudden expansion as shown in the figure.

Compressibility effects have been identified to reduce the

recirculation zone behind the step. Control of the cold flow using

a suction slot at the step corner has been shown to be an effective

destabilizer of the shear layer and to

enhance mixing behind the step. Droplet mixing and deposition

is strongly dependent on the injection location in the boundary

layer. Current efforts focus on further parametric studies

to identify the combustion physics, and computations of more

complex combustor geometries.

|

| Collaborators: |

Dr. F. Mashayek (University of Illinois at Chicago),

K. Sengupta (University of Illinois at Chicago) |

| Home | Research | Teaching | Publications | Group | Resume |